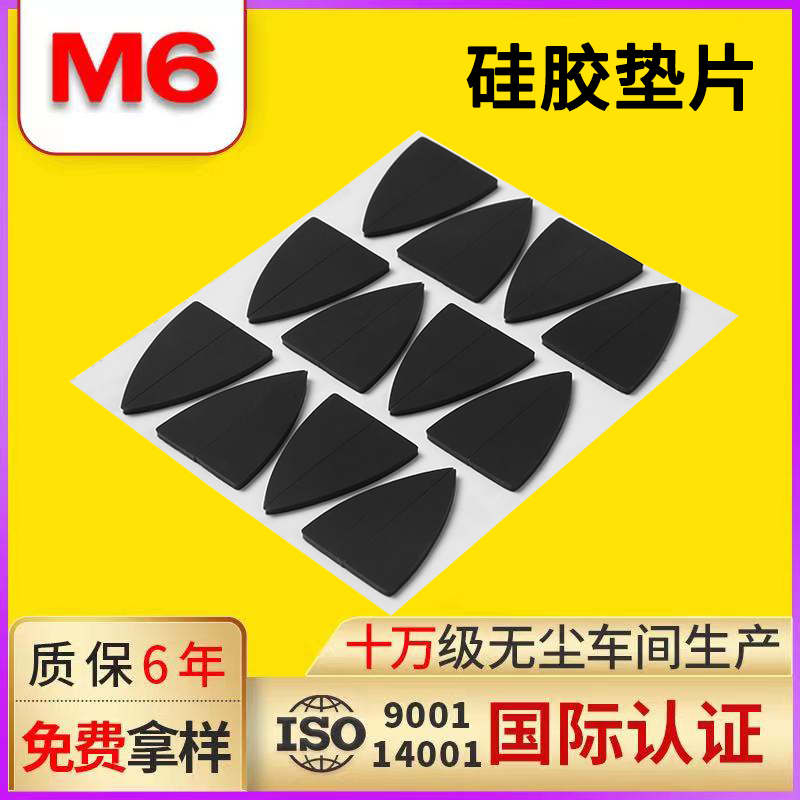

Automotive thermally conductive silicone film m6 brand

- Product Model:M6-00735643

- Production Cycle:1-7days

- Minimum Order Quantity:1000PCS

Thermally conductive silicone is applied to the surface of the treated substrate by the mixed patch during treatment, and the force is applied evenly during application, and repeated pressing is used to ensure that the material is in full contact with the surface of the substrate to achieve the best effect. When multiple layers of glue are required, the original adhesive surface needs to be treated before applying.

Thermal adhesives replace the traditional way of connecting cards and screws. Thermal conductive adhesive is now widely used in industrial production, and is called by the majority of users: thermal conductive adhesive, thermal silicone, thermal insulation adhesive, thermal conductive material, thermal silicone, LED thermal conductive silicone and so on. Dongguan Sanxin Packaging Products Co., Ltd. products involve electronic special industrial tape, imported tape, adhesive mat.

Thermal conductive adhesive curing speed is fast, easy to extrude, but does not flow, easy to operate, can be manually sizing can also be mechanically sizing, no glue leakage, to meet any working environment and working conditions, with the benefits of simple and convenient sizing. Dongguan Sanxin Packaging Products Co., Ltd. is a die-cutting processing technology as the main body, professional sales and service as the fundamental processing manufacturers. Products are committed to the processing and development of adhesive paper and peripheral products, serving mobile phones, notebook computers, digital cameras, MP3, PDA, DVD, LED, LCD displays, electronics, electrical appliances, communications, medical and automotive industries. The products involve electronic special industrial tape, imported tape, adhesive foot pad. Welcome to inquire, our company can design proofing for customers for free!