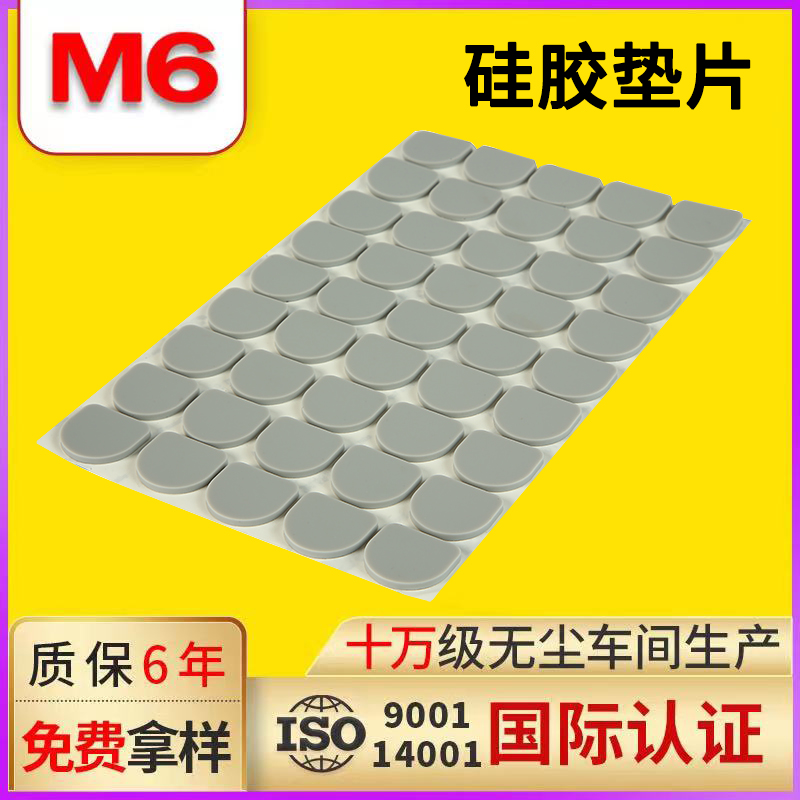

m6 industrial brand round silicone double-sided adhesive sticker mahogany furniture foot mat anti-slip gasket electrical and electronic supplies mat

- Product Model:M6-00735625

- Production Cycle:1-7days

- Minimum Order Quantity:1000PCS

Silicone has high temperature resistance, aging resistance, softness, ozone resistance, weather resistance, high and low temperature resistance and other properties, the color can be done a variety, hardness is generally between 30-70 degrees, high temperature resistance -40 degrees to 300 degrees or so, and conventional organic elastomers compared with silicone rubber is also particularly easy to process and manufacture. Silicone rubber flows easily, so it can be molded, calendered, and extruded with low energy consumption. Easy processing also means high productivity.

Main features:

Resistance to high and low temperature stability

Inert (tasteless and odorless)

Transparent and easy to color

Wide hardness range, 10-80 Sauer hardness

Resistant to chemicals

Good sealing performance

Electrical properties

Resistant to compression deformation

The reasons for the failure of the silicone binder gasket are first of all the following situations:

1. The pressure acting on the sealing gasket is missing. Since there are always microscopic bumps on the sealing surface, and sometimes a number of annular grooves are processed on the sealing surface, if the sealing is guaranteed, a sufficient pressure must be applied to the sealing gasket to cause it to undergo elastic or plastic deformation to fill these open spaces. The compression force of various gasket materials is generally given in the sealing gasket manufacturer sample or product manual, and can also be selected through experiments. The compression force required for the gasket is not reached when the device is not reached, or the compression force is reduced due to the loosening of the compression bolt by the vibration in normal operation, and the elasticity of the original is lost due to the aging deformation of the gasket material will cause the gasket to fail and leak.

2, silicone loose seal gasket internal tissue or thickness is not uniform, and the use of cracks or creases of the cardboard, so that the gasket itself formed a vacant land, when the force acting on the gasket so that the elastic deformation of the gasket is not enough to completely fill these open spaces, leakage is inevitable.

3. The material of the silicone live-knot sealing gasket is not suitable for the medium being transported. Due to the diversity of chemical properties of the chemical products transported by the pump, as well as the addition of some small amount of additives to the fuel in order to advance the combustion value of the fuel or change its combustion products and change some properties of the fuel, it is not easy to select the gas for the transport medium, so it is often possible to cause the gasket to corrode due to incompatibility and leakage.