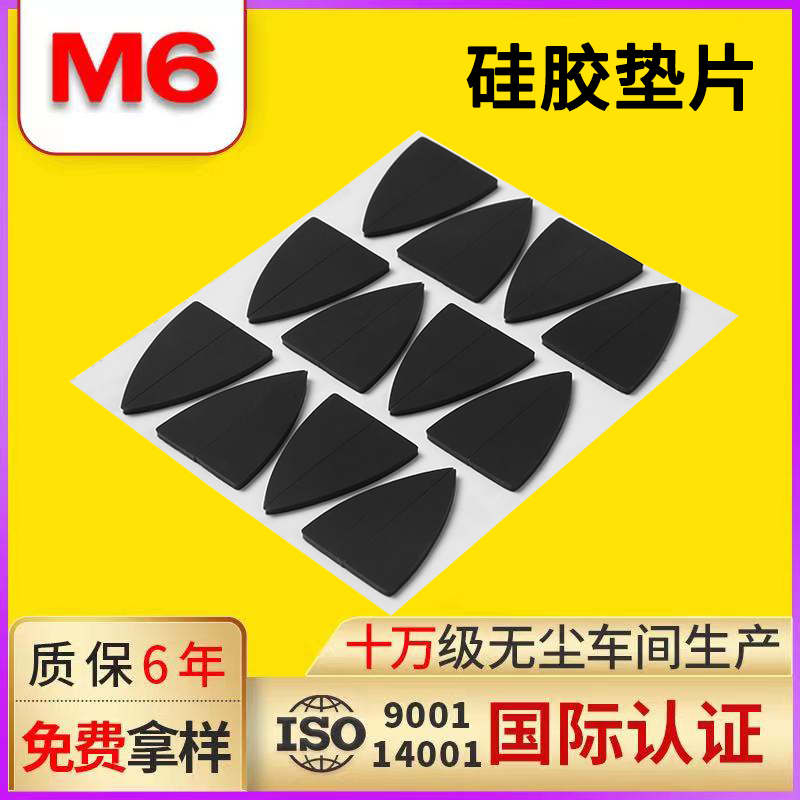

m6 industrial brand off-white silicone foot pad Sealed silicone gasket self-adhesive silicone anti-slip mat Transparent silicone pad waterproof silicone pad

- Product Model:M6-00735613

- Production Cycle:1-7days

- Minimum Order Quantity:1000PCS

Basic properties of the material:

1. Anti-aging: Has a long service life in harsh environments and is not affected by weather, including rain, snow, humidity, ozone or damaged ultraviolet (UV).

2. High and low temperature resistance: maintain its flexibility and elasticity in a wide temperature range ( -60-300 degrees Celsius use range)

3. When exposed to harsh environmental stresses, its good electrical insulation properties will not change significantly.

4. Improve the comfort, texture and touch of consumer goods.

5. Good sealing performance

6. The inertness (odorless, odorless) makes it ideal for a variety of food contacts

7. Wide range of color options (from transparent to bright colors)

Glass rubber mat production process:

1, raw materials

The bulk raw rubber raw materials are crushed, the wet raw materials are dried, and the iron-containing raw materials are treated with iron removal to ensure the quality of the glass glue pads.

2. Melting

The bulk glass rubber pad compound is heated at high temperature (1550~ 1600 degrees) in the pool kiln or crucible kiln to form a uniform, bubble-free liquid glass rubber pad that meets the molding requirements.

3, molding

The liquid glass rubber pad is vulcanized at high temperature, so that the raw rubber raw materials become solid molding.

4. Trimming

The product that comes out of the mold will be accompanied by some useless burr that needs to be removed; currently, in the industry, this process is completely done by hand.

5. Glue

The surface of the molded glass rubber pad is specially treated, and then fitted to the domestic 90U (95U) double-sided oil tape, 3M tape, TESA tape, NITTO tape, SONY tape, T4000 tape, polar bear tape and so on.

6. Stamping

The molded product is stamped with a punching machine according to the actual required specifications.