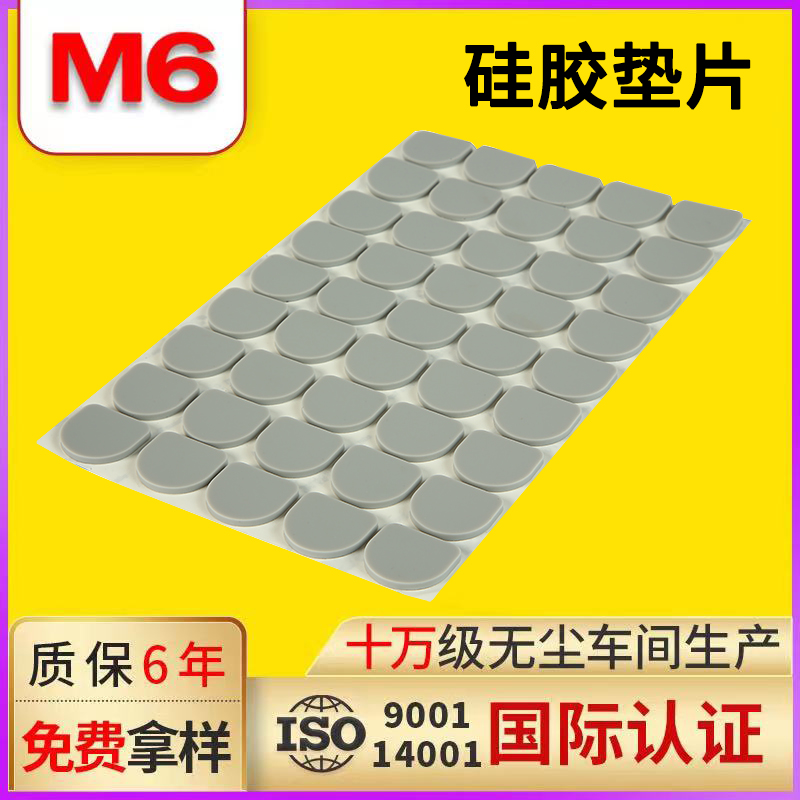

m6 brand silicone sealing mat computer fan color gasket automotive instrument desk self-adhesive silicone anti-slip mat digital instrument shock resistant foot pad

- Product Model:M6-00735604

- Production Cycle:1-7days

- Minimum Order Quantity:1000PCS

Product production process:

1. Raw material preparation: raw rubber raw materials, transparent agents, accelerators and other raw materials are proportionately mixed.

2, rubber refining: after a certain temperature, the prepared raw rubber is mixed with the rubber compound and additives evenly, refined, so that the transparency of the produced products is consistent.

3, material: according to the size of the product specifications, the size of the mold, the material slice.

4, vulcanization molding: with a high-pressure vulcanizing machine through 300 degrees of high temperature vulcanization molding, so that the raw material of the rubber material curing molding.

5, trimming: the semi-finished product molded by the vulcanizing machine has completed the hardness, specifications, transparency of the product, and the product pressed out from the mold will be accompanied by some useless edge materials, which need to be manually trimmed and removed.

6, surface treatment: because the surface of the transparent rubber pad does not absorb glue, in order to be able to fit firmly with a variety of double-sided adhesives, the surface of the adhesive should be destroyed with a special treatment agent to destroy the surface tissue of the adhesive surface, so that the double-sided adhesive is not easy to fall off after lamination, and the viscosity is firm.

7. Adhesive: According to the specified requirements of the guests, the products after surface treatment are pasted with double-sided adhesive with different viscosities, and the pieces of double-sided adhesive are generally: ordinary double-sided adhesive: 80-150μ, 3M double-sided adhesive, NITTO (Nitto) double-sided adhesive, NIKKO (Daylight) double-sided adhesive, TESA (Desha) double-sided adhesive, SONY (Sony) double-sided adhesive, DIC (Great Japan) double-sided adhesive, SEKISU (waterlogged double-sided adhesive), comprehensive research double-sided adhesive, Nico double-sided adhesive and other double-sided adhesive fitting.

8, punching type: according to the specified specifications with a set of punching knife die punching into the batch stereotype of the product, the general stamping is half broken, half broken is a rubber pad has dozens to hundreds of grains, the above adhesive and double-sided adhesive have broken, the following release paper is not punched through, so that in the use of the guest in the process of easy to operate, easy to tear.

9, selection: after the product punching type is good, a rubber pad inside in the previous production process, sometimes there will be some black spots, glue is not ripe bad products, flushed crooked, and then manually pick out the bad products one by one, and then use good products to make up for it, so that it is made into a finished product of transparent rubber pads.

10, packaging: the general packaging is the use of thickened film to wrap the finished transparent rubber pad according to the multiple of 100 or 100, and then into the box.

Product viscosity:

It can be fitted with 3M Nichidong Sony Great Japan Back Pole Bear Comprehensive Research Desha Hitachi Hitachi Waterlogging and other brands of double-sided adhesive, and can also be produced according to the specified double-sided adhesive.

Product performance:

High transparency, strong viscosity, aging, oil resistance, wear resistance

Product Use:

Electronic appliances Hardware plastic glass crafts Ceramic crafts Solid wood furniture Kitchen cabinet doors and windows