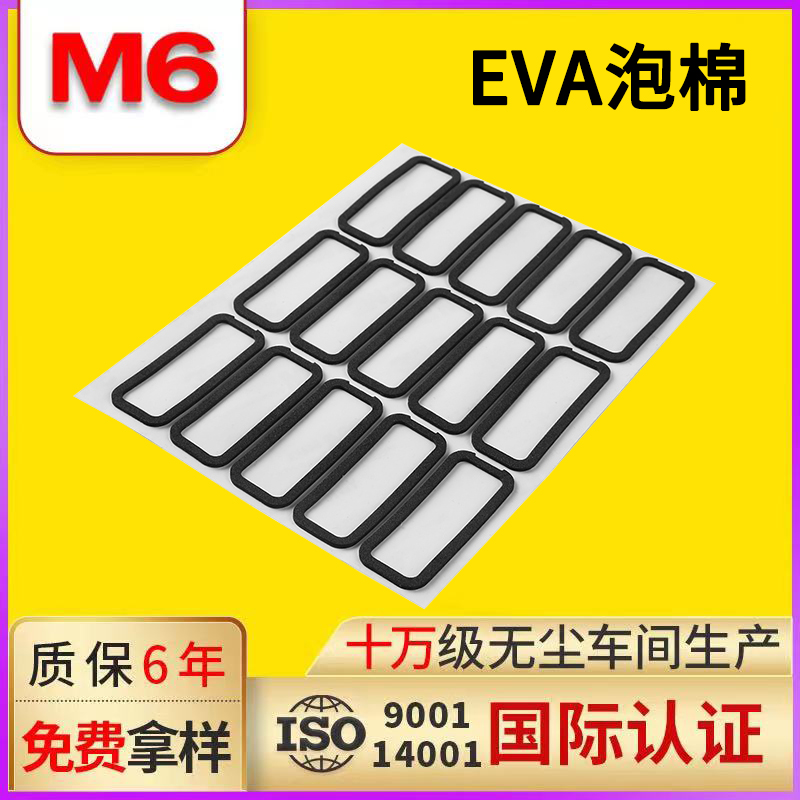

m6 brand single-sided back 3M double-sided adhesive EVA environmental foam pad EVA gasket anti-static mobile game joystick suction cup conductive sponge foam foam self-adhesive

- Product Model:M6-00735626

- Production Cycle:1-7days

- Minimum Order Quantity:1000PCS

EVA foam packaging EVA engraving molding EVA lining EVA foam manufacturers integrated molding lining EVA products production. EVA foam packaging lining using CNC computer engraving machine, integrated molding production, and the traditional knife mold viscose process has many advantages: 1. The product is integrated, no viscose traces, with 3D effect. 2. The production process does not require molds, there is no additional cost to replace the contents, and it can support a small number of diversified orders, MOQ: 5PCS. 3.EVA foam packaging lining, rubber mat texture soft, environmental protection and non-toxic and tasteless, high-grade appearance, low comprehensive cost, can effectively improve the added value of the packaged products (Note: the company's special machinery, process cost is usually lower than the same industry about 10% less) 4.EVA foam elasticity, strong impact resistance, moderate PH value, good sealing, chemical corrosion resistance, oil and oxidation resistance, can safely and effectively protect all kinds of vulnerable parts or finished products. 5. The industry takes the lead in adopting a two-color electric heating benzene-free composite structure, the color of pearl cotton packaging is clear and variable, it is more convenient to pick up and place products, and there are also standard colors to choose from.

Anti-static EVA is in accordance with the index of 107ΩM2 tuning, all with the production of genuine incoming materials, is a permanent anti-static products, the electrostatic index is accurately controlled within 106-108ΩM2 (according to the standard hammer test), anti-static EVA is widely used in the field of electronic gaskets and advanced electronic packaging, is Foxconn electronic products permanent anti-static EVA designated supplier.