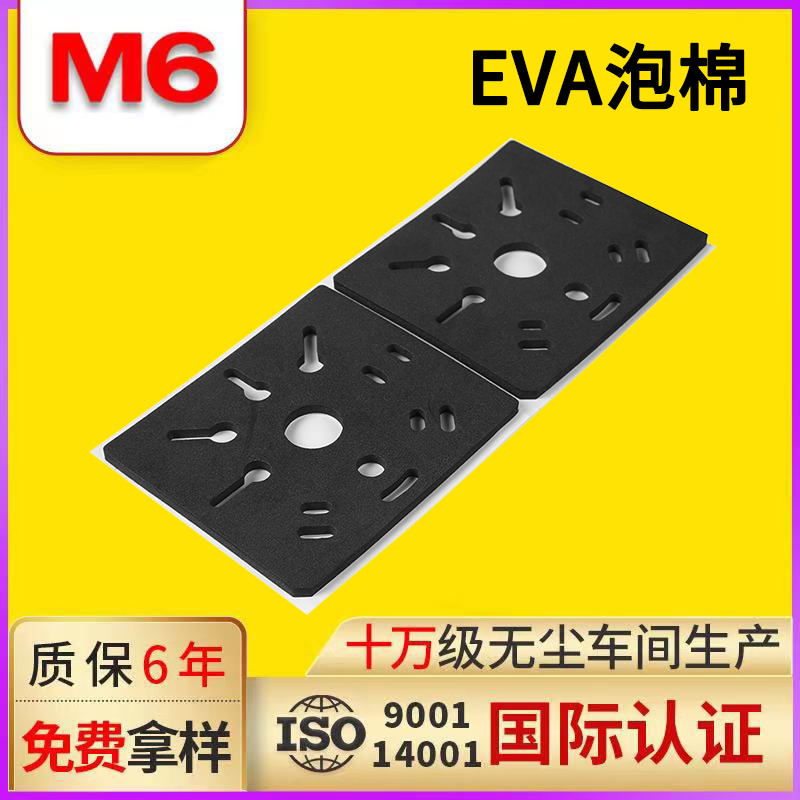

EVA self-adhesive foot pad M6 brand

- Product Model:M6-00735639

- Production Cycle:1-7days

- Minimum Order Quantity:1000PCS

Regarding the problem of EVA foam chip dust, the root cause of this problem is caused by the characteristics of the foam itself, due to the low toughness of the foam, the composition structure is foam material, all in the process of punching and cutting, because of the repeated action of the tool, the chip foam particles are easy to form dust and float in the air. For some die-cutting operations with clean requirements, there are many ways to solve such problems, generally common is to spray mold release agents, and the method often used on the production line is to combine a layer of OPP protective film on the surface of EVA foam to solve this problem. Of course, such a solution may cause some waste of excipients.

EVA material is characterized by good softness, rubber-like elasticity, at 50 ° C can still have good flexibility, transparency and surface gloss, good chemical stability, anti-aging and ozone strength is good, non-toxic. Good blending with fillers, good coloring and molding processability.