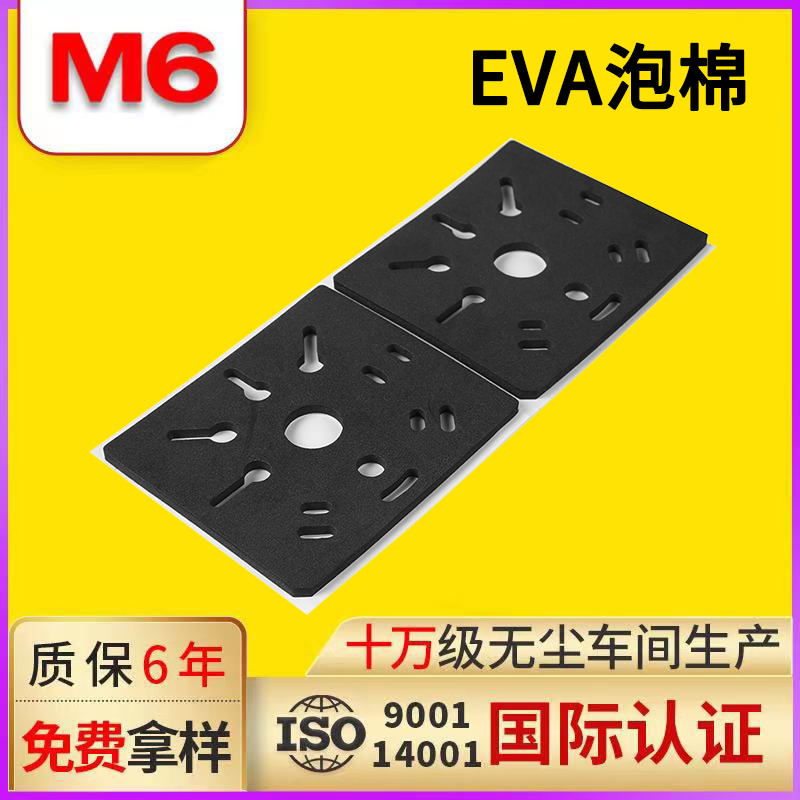

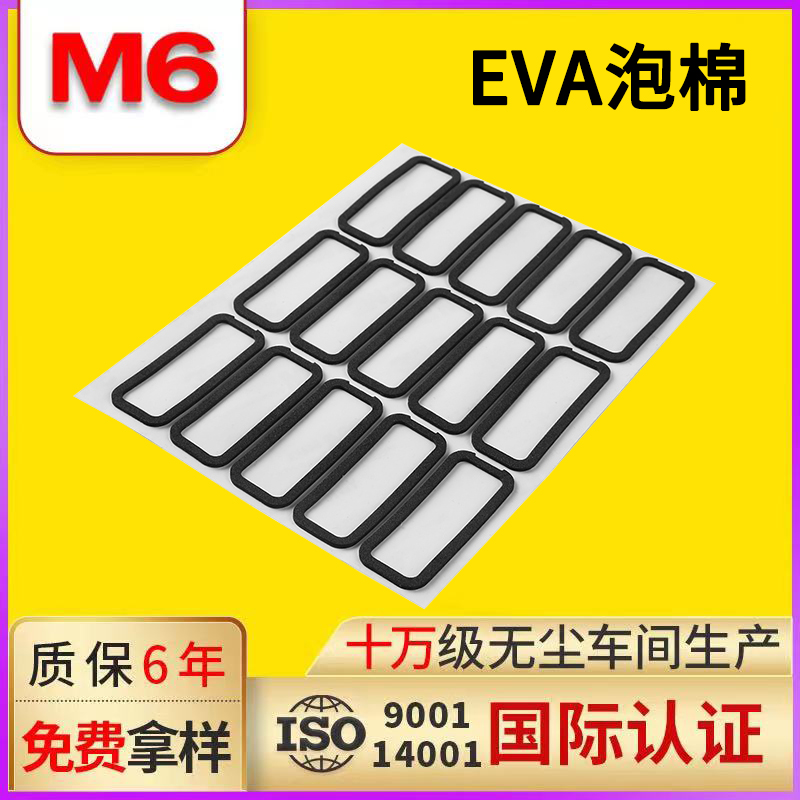

Eco-friendly EVA foam rubber mat m6 brand

- Product Model:M6-00735637

- Production Cycle:1-7days

- Minimum Order Quantity:1000PCS

Because of the material characteristics of EVA, there are very high requirements when EVA is processed and formed. According to its harsh requirements such as solar cell service life and anti-aging, many domestic manufacturers have finally made significant progress in formulation after continuous repeated tests. Most of the domestic EVA film has reached the level (all indicators are in line with the requirements, some indicators exceed foreign products).

Due to the demanding requirements of the photovoltaic industry, the requirements for EVA production equipment are also very high. The stability of the equipment and the control of the shrinkage rate affect the loss of its formulation ingredients as little as possible. There are many manufacturers of adhesive film equipment in China, but they are more or less up to the requirements. As a result, many EVA manufacturers choose to assemble or assemble their own equipment. Until 2010, there was a production enterprise of the entire EVA film production line in China (Dongguan Sanxin Packaging Products Co., Ltd.). China's pace of development in the EVA industry is faster. Reduced the cost of EVA film, indirectly reduced cost of the photovoltaic industry. Dongguan Sanxin Packaging Products Co., Ltd. is a set of sales and service as one, new technology die-cutting business enterprises, specially committed to providing customers with professional die-cutting product solutions, products widely used in clothing, electronics, hardware, amplifier audio, computers, automotive electronics, security fields. Consumer electronics, communication equipment, industrial control and other industries!