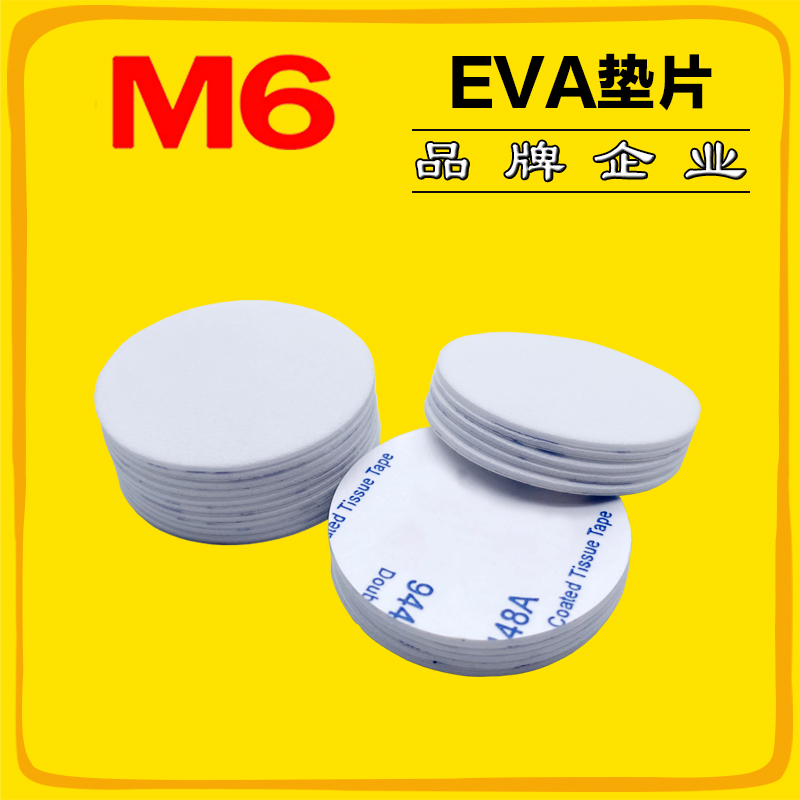

m6 industrial brand electronic EVA cushioning gasket round paste foam gasket sponge patch foam gasket non-slip black single-sided adhesive shock absorption waterproof

- Product Model:M6-00735618

- Production Cycle:1-7days

- Minimum Order Quantity:1000PCS

The processing techniques we can use:

Horizontal/Vertical Cutting: Simple slitting of materials, which can cut different thicknesses and simple flat shapes.

Stamping and cutting: the use of mold cutting, can be processed out of complex shape curves, high dimensional accuracy.

Drilling and cutting: Using tools and fixtures, it is possible to process high-precision through holes and blind holes.

Wire cutting: used for large arc foam semi-circular columns, triangles, trapezoidal and other three-dimensional arc cutting molding.

Hot pressing: Using a hot pressing mold, the simple flat sponge is processed into a complex curve shape, which can mainly press out a very good three-dimensional concave and convex effect.

Adhesive tape bonding: Paste sticker on sponge.

Glue bonding: Glue is applied to the surface of the sponge and then fitted with other materials.

Corrosion resistance: resistant to seawater, grease, acid, alkali and other chemicals corrosion, antibacterial, non-toxic, tasteless, non-polluting.

Processability: no joints, and easy to carry out hot pressing, cutting, gluing, laminating and other processing.

Anti-vibration: high resilience and tension resistance, strong toughness, with good shockproof/cushioning performance.

Thermal insulation: heat insulation, thermal insulation and cold protection and low temperature performance is excellent, can withstand severe cold and exposure.

Sound insulation: closed bubble holes, good sound insulation effect.